Basic HTML Version

•

•

•

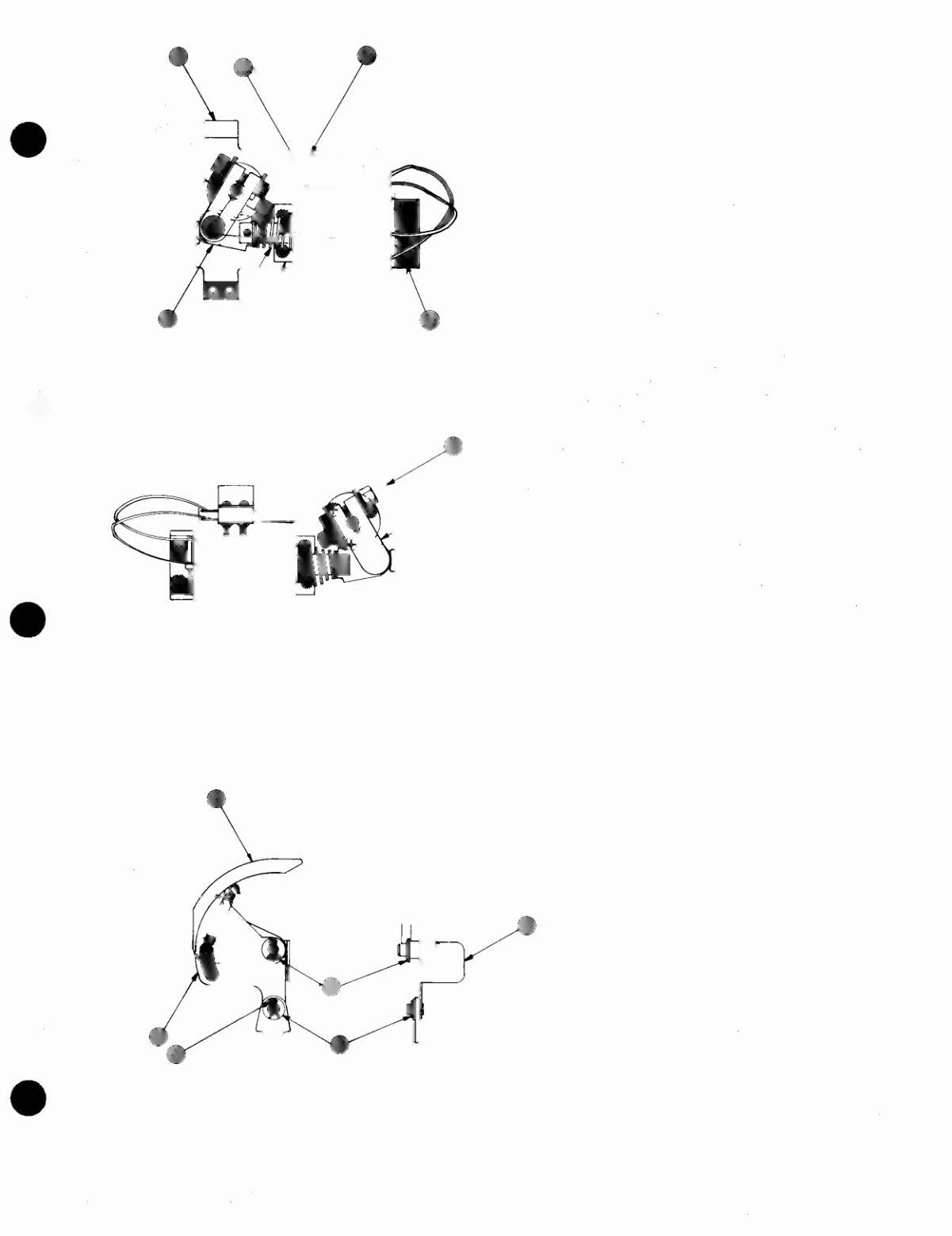

C-9952-R FLIPPER ASSEMBLIES

ITEM PART NO.

DESCRIPTION

1

B·10655·R

Crank Link Assembly

2

C·9954·R

Flipper Base/Lane Change Assembly

2a

03·7811

End of Stroke ~ Switch

2b

SW·1A·150

Lane Change

WI

ch

2c

03·7568

Flipper Bushing

2d

A·10280

Flipper Stock Bracket Assembly

3

01·7695

Solenoid Bracket

4

10·376

Coil Plunger Spring

5

FL 23/600·30/2600 Flipper Coil

6

23·6577

Bumper Plug

NOTES:

1 Each Flipper Assembly is mounted below Ihe playfield,

in con-

junction with the plastic flipper and shaft (20·9250) and flipper

rubber (23·6519) (on the upper side of Ihe playfield).

2 The tip of the EOS Switch must travel

.015 (~.010,

- .000 inch),

before the contacts fully open with the flipper in the actualed

position.

The EOS Switch contacts must have a gap of .062

(:!:

.015) inch. Any adjustment

of the EOS Switch must be made at

a minimum distance of .25 inch from the switch body

3 The Lane Change Switch musl have a gap of .046

(:!:

.015) inch,

when fully open

4 All moving elements of the assembly must operate freely without

any evidence of binding

5 Coil plunger spring must fit within the four lugs of the solenoid

bracket

6 For coil

replacement,

remove solenoid bracket. (item 3) to pre-

vent screw damage

Use Loclite when reassembling flipper stop bracket screws.

8 When using bumper plug on older flipper assemblies,

readjust

flipper position.

9 Solid color grey (or blue) wire connects to the banded end of the

diode, mounted on the connector end of flipper coil (item 5). Wire

with trace color connects to the unbanded end of the diode.

2

C-9953-L UNIQUE PARTS

ITEM PART NO.

DESCRIPTION

1

2

B·10655·L

C·9957-L

Crank Link Assembly, Left

Flipper Sub Base Assembly

3

2

B-9361-R-3 BALL EJECT

ASSEMBLY-RIGHT

ITEM PART NO.

DESCRIPTION

1

A·6949·R

Spring Plate

2

A·6950·R

Mounting Bracket Assembly

3

A-7471-R

Eject Cam Assembly

4

A·5103

Coil Plunger Assembly

5

10-362

Spring·Eject

6

12·6227

Hair Pin Clip

7

4700·00030·00 17/64 x 1/2 x 15G

8

4700·00103·00 17/64 x 1/2 x .015